JAPAN

Hall B

BB4-7

Manufacturing Automation, Machinery, Equipment, Materials & Accessories, Process Automation Systems, Equipment, Materials & Accessories, Cleaning Devices & Clean Air Systems

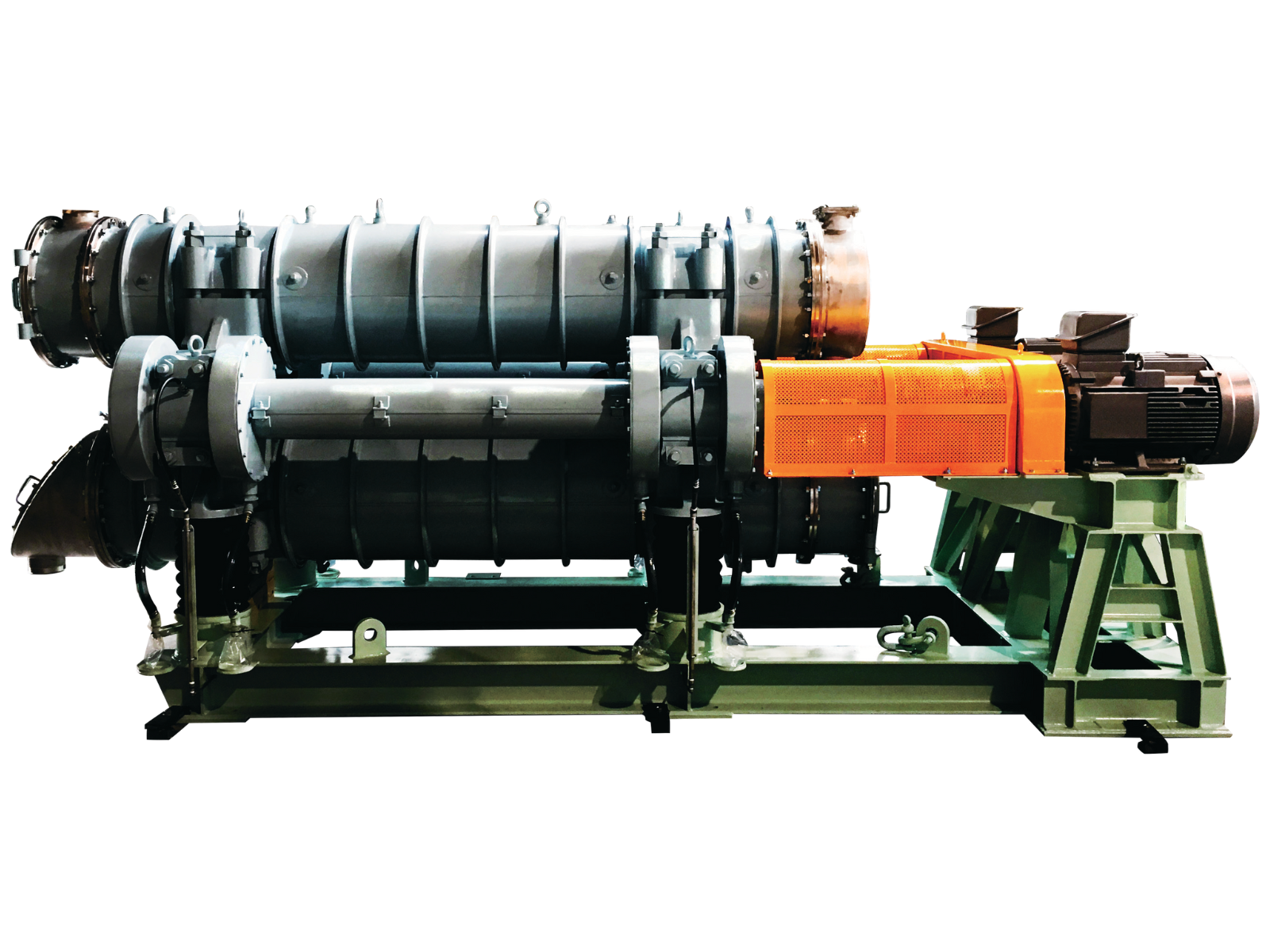

The vibration mill operates by inducing high-speed circular vibration using springs.

The vibration energy is transmitted to the media (balls or rods) inside the milling tube, where the materials are finely milled

in a short time by the simultaneous action of intense impact, friction, and shear between the media and the inner wall of the milling tube, and between the media themselves.

The milling efficiency is 10-20 times that of a rotary ball mill.

1. Milling speed is 10-20 times faster than a rotary ball mill.

2. A wide range of milling is possible, from medium to fine milling.

3. Both dry and wet milling are possible.

4. All parts are detachable, making replacement and maintenance easy.

5. The materials for the lining and media inside the can body can be selected (e.g., iron, stainless steel, alumina, zirconia, rubber, nylon).

6. Special milling, such as inert gas filling is possible.

New in Vietnam – To be showcased in Vietnam for the first time