CHINA

2

2207

Data Acquisition / Processing / Transmission, Inspection / Testing / Quality Control Equipment, Pipeline Engineering

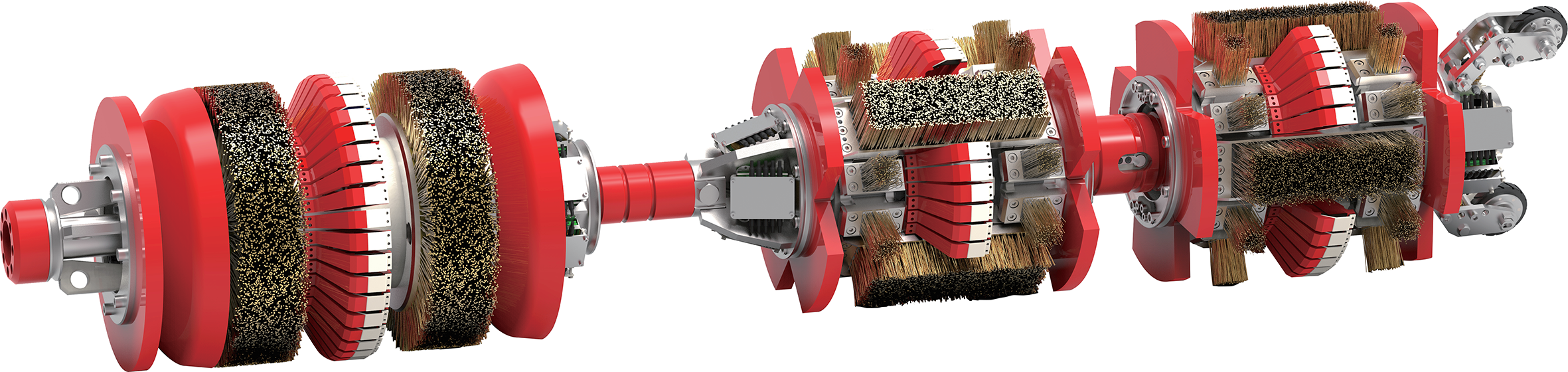

The MFL+TFI tool is composed of an axial excitation detection section and a circumferential excitation detection section. Circumferential excitation detection magnetic field is distributed along the circumferential direction of the pipe wall, which can detect axial defect signals, and has strong detection ability for axial grooves. Axial excitation detection data and circumferential excitation detection data complement each other to realize omni-directional detection.

KEY ADVANTAGES:

Improved detection ability of axial groove defects: The circumferential excitation detection structure improves the ability of axial groove detection, and can detect axial groove defects with 0

Data Acquisition / Processing / Transmission

Inspection / Testing / Quality Control Equipment

Pipeline Engineering